The laser apparatus itself cannot damage the metal conductor, so with nearly complete elimination of error, this could maximize yields and ultimately reduce overall costs.

#Using wire strippers manual

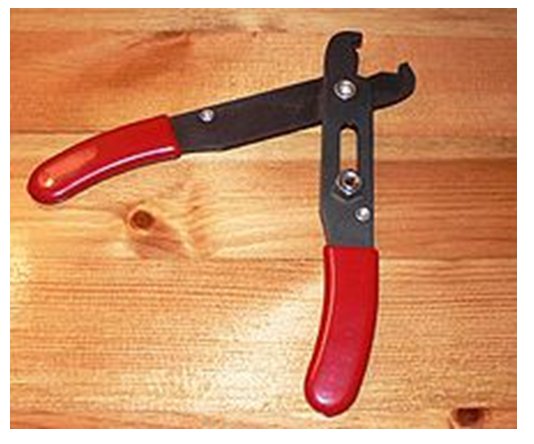

They currently provide the highest achievable strip quality out of any products on the market, eliminating the possibility of previous manual errors that could cause delays and additional expenses in a variety of projects. The benefits of laser wire strippers surpass that of traditional wire strippers, particularly when taking into account their feasibility and quality of execution. Advantages and Disadvantages of Laser Wire Strippers Benefits Regardless of the ultimate need for these machines in any job, they exhibit major benefits in comparison to conventional methods. These projects could easily range from simple electrical circuits as found in your home, to life-saving medical devices, or even complex astronautical machines that will someday leave the planet. The possibilities are seemingly endless regarding projects that could involve laser wire stripping. These wires stray from the stereotypical shape and functionality. More labor-intensive instances typically involve complicated wire shapes, bonded insulators, ribbon cables, or other wires. Aside from cutting high-quality cables, laser wire strippers are practical in scenarios with an abundance of labor-intensive wire cuts. It executes a quick and precise cut with no residue, perfect for very fine wires used in important medical devices like catheters or pacemakers, where conduction reliability is vital. Lasers are a perfect alternative to manual wire stripping when using thinner wires of higher monetary value. Bigger units like these increase efficiency rates and save time since they can process multiple wires and/or cables simultaneously. That system is a benchtop unit with a dual axis, which enables it to execute these intricate strip patterns at any point along the length or circumference of the wire. The laser wire stripper, shown in Figure 2 above, is an example of one of these further advanced systems. These complicated strip patterns are ideal for fiberglass or cloth materials. Heavier insulators require higher-powered stripping systems, entailing more modern methods that can execute complex strip patterns. If a more complex strip form is desired, the wire will then angle itself in accordance with the desired cut. Alternatively, depending on the type of machine, the cable can rotate while the laser remains stationary. Next, the laser moves along the circumference of the wire, stripping the desired area of insulation from the conductor. This is done by special lenses which direct and focus the laser beam precisely onto the area to be stripped. To achieve a precise cut, the laser beam must first be focused onto the very exact position where it is needed. As the laser’s energy is absorbed by the surrounding insulating material, it vaporizes under intense heat and pressure. The Technology IntroductionĪt the core of laser wire strippers is the process of melting and ablating insulation coating by a laser beam. The lasers allowed for new levels of precision and control, during a process that was once considered extremely tedious. They later became exceedingly popular in the aeronautical, defense, and medical markets across a variety of electrical projects. The machines were initially created to overcome problems encountered in the electrical development of the first Space Shuttle, Enterprise. These are my top pick reviews and are written to help you choose the best tool for your purpose, allowing you to do more in less time, improving your job performance.Laser Wire Strippers were first created and tested by the National Aeronautics and Space Administration in the nineteen-seventies. So today, I’m going to review the twelve best wire stripping pliers I’ve seen or used. You’ll definitely save time and manpower if you have an electrician wire stripping tool. It doesn’t even include the other tasks where I’ve saved even more time. This small device would save me at least seven hours per home in outlet installation only. On average, each home has seventy outlets. I found that an experienced worker can save at least one minute per wire or six minutes per outlet. I’ve once experimented comparing outlet installations using a pair of pliers versus electrician wire strippers.

#Using wire strippers professional

However, if you’re a professional electrician working with miles upon miles of wiring, having the best wire stripper on hand is a life-saver.Ī cable stripping tool can save you time and effort, especially if you’re wiring an entire house. Many people think that stripping wires is such a mundane job that a good wire stripping tool is just a luxury. Knoweasy Automatic Wire Stripper has been repeatedly selected as one of the top 10 best-selling wire strippers of 2020, and is recognized by the market as an excellent wire stripper!

0 kommentar(er)

0 kommentar(er)